I'm going to address this bit of nonsense one more time.

There is a company in Houston, Build Clean, that has resurrected the Radon in Granite myth, again. There are a few things to be aware of:

1] About 1/2 their funding comes from the company that makes Silestone, an engineered gravel alternative to Granite.

2] The other 1/2 comes from Cambria, another engineered gravel company.

3] The national marketing director for Cambria sits on the Build Clean board.

4] One of the major Radon testing kit manufacturers is owned by the parent company who also makes Silestone.

See any pattern here? The old adage 'Follow the Money' couldn't be much clearer.

Here are the results from an independent study on this subject:

"New Study Confirms Safety of Granite Countertops

Cleveland, OH , May 14, 2008 The Marble Institute of American has announced the conclusion of a recently conducted scientific study of thirteen of the most popular granites used for kitchen countertops in the United States during 2007. The study confirms that granite is a safe material for use in kitchens.

The issue of granite containing radon has surfaced repeatedly over the years. The origins of these concerns are advertisements and other communications from the manufacturers of radon detection devices and the manufacturers of competing synthetic countertop materials. Each time these concerns have arisen, the Marble Institute of America, as well as several producing companies, has responded by thoroughly researching the issue to determine if potential health hazards actually exist.

MIAs most recent testing was conducted by L. L. Chyi, a Ph.D. and professor of Geochemistry and Environmental Geology at The University of Akron, Akron , Ohio . Dr. Chyi studied 13 of the most popular granites used throughout the United States as determined by an industry-wide survey. Due to their popularity these 13 granites, are believed to represent up to 85% of the granite countertop market in recent years. The granite types are as follows:

New Venetian Gold, Brazil; medium grained, yellow-beige gneiss with many dark red garnets.

Uba Tuba , Brazil ; A medium- to coarse grained, olive-green granite.

Santa Cecilia , Brazil ; A coarse-grained, yellow-grey gneiss with up to pie-sized, red garnets.

Tropic Brown, Saudi Arabia; medium-grained, brown granite.

Absolute Black, India; black basalt.

Tan Brown, India; A black-brown igneous rock with big, shapeless, brown-red feldspar crystals.

Giallo Ornamental , Brazil ; coarse-grained, brown-yellow granulite with some brown-red garnets.

Crema Bordeaux, Brazil; Juparana Crema Bordeaux (Brunello). A coarse- to very coarse-grained, pink to red granite with areas of quartz, alkali feldspar and quite a lot of ore.

Baltic Brown, Finland; brown-black granite.

Giallo Veneziano , Brazil ; medium- to coarse-grained, ochre-yellow to golden-brown, also light pink, gneiss.

Dakota Mahogany, USA; medium- to coarse-grained, brown-red granite.

China Black, China, a fine-grained plutonic rock.

Yellow Star, China, a medium-grained yellow to pink granite.

The testing methodology was designed to measure the amount of radon which each granite type would add to the interior of a 2,000 square foot, normally ventilated home with 8 ft ceilings.. The results show that Crema Bordeaux (the most active in terms of radon emissions) would contribute a concentration component of less than 0.28 pCi/L, or less than 7% of the EPA's recommended actionable level of 4.0 pCi/L. This radon amount is well below a level which might cause health concerns. Tropic Brown and Baltic Brown, second and third in radon emanation based upon Dr. Chyis testing, amounted to only 1% of this action level. The other granites tested added almost immeasurable amounts of radon to the house.

Dr. Chyis test results show that the granites that are currently found in the United States market place are insignificant contributors to radon levels in the home. Based on the testing results and EPA standards, we can conclude that the most popular granites used as countertop surfaces pose no health threat to homeowners. The test results are available on MIAs website, http://www.marble-institute.com/industryresources/radontesting_u-akron2008.pdf. "

Radon is a naturally occurring gas that is everywhere. The primary source of it is in the earth beneath your feet. Some areas have more than others. In that case, there are remedies for it.

If Radon were the raging concern painted by the engineered gravel people, 1/2 of Europe would be uninhabitable, since stone is everywhere over there. And, it has been for years.

Thursday, May 15, 2008

Friday, April 18, 2008

Counter top heights

If you've been in the remodeling industry for a number of years, this won't be news. However, if you are a normal human, I'm going to address the issue and ramifications of counter top height.

Since we do so many remodels, we are often asked to try and save an existing backsplash. Mostly, we replace formica counters with stone counters. A 'normal' base cabinet is 34.5 inches tall. A 'normal' finished counter height is 36 inches tall. The typical method to prep for formica is to strip out the tops of the cabinets with 1X2's. These are placed around the perimeter of the cabinets and across the tops of the bulkheads of the cabinets. Then, a sheet of 3/4" plywood is placed on top of the furring strips. Then a 1X2 band board is place around the outside perimeter of the cabinets, nailed into the side of the 3/4" plywood. This covers the 1X2 furring strips. Formica is then glued to the top of the plywood and glued to the face of the band board. The top intersection edge is usually beveled so you get that black line that runs around the edge of the cabinets. The backsplash is then placed on top of the formica. Usually, it is tile.

When replacement time comes, here is what you are faced with: 2cm, 3cm or 4cm [laminated] granite tops. 2cm=3/4". 3cm=1 and 1/8". 4cm is two pieces of 2cm glued together. Be mindful that 2cm may actually be 11/16" or it could be 7/8". It depends on who produced it. The same variables apply to 3cm.

So, if you are wanting to save your backsplash, remember it is going to start at 36" off the floor. Once the formica is stripped off, your base cabinet is going to be 34.5" off the floor. So, if you use 2cm or 3cm, there is going to be a gap somewhere. Either on the bottom of the granite, or between the top of the new counter and the existing tile backs.

If you do 4cm, you can re-strip the cabinets with 1X2 furring strips and the laminated edge will cover the furring strips. The counter height should match the existing tile, or within a caulkable margin. The problem here is two-fold. One, you must 'handle' the material about 5 times to get a tight lamination. It is not a matter of simply gluing a secondary piece on the bottom and calling it good. Thus, with all the additional handling, the costs go up.

The second problem is grain match. As people's tastes in stone continue to get more sophisticated, they tend to like unique stone with movement. If all your cabinets are straight runs, no big deal. We can make the grain match. Got any funky angles, big round corners, want the top grains to match properly? Big problems. With any of these conditions, something has to give. And what 'gives' is grain match. So, if the grain match is no big deal to you, this solution will work. However, most of our clients expect it to be right [as do we], so lets go back to 2cm or 3cm.

Furr up the tops to meet the backsplash and run a piece of wood trim under the tops to hide the height variation. This works.

Leave the counters on top of the cabinets and run a piece of tile trim or stone trim to cover the void between the counters and backsplash. This works.

Now, lets look at economics. I'm going to use some 'average' numbers. Let's say you are putting in some very nice 3cm granite. Let's say it will cost $4000. The average backsplash will cost [labor and material] about $350. Am I going to go into contortions trying to save the $350 component? Economically, no.

There are always variables, and if you have individual questions, I'll be happy to answer them, but this should give you a basic overview of some considerations you might want to ponder. No one likes expensive surprises. We would be included in that group.

Since we do so many remodels, we are often asked to try and save an existing backsplash. Mostly, we replace formica counters with stone counters. A 'normal' base cabinet is 34.5 inches tall. A 'normal' finished counter height is 36 inches tall. The typical method to prep for formica is to strip out the tops of the cabinets with 1X2's. These are placed around the perimeter of the cabinets and across the tops of the bulkheads of the cabinets. Then, a sheet of 3/4" plywood is placed on top of the furring strips. Then a 1X2 band board is place around the outside perimeter of the cabinets, nailed into the side of the 3/4" plywood. This covers the 1X2 furring strips. Formica is then glued to the top of the plywood and glued to the face of the band board. The top intersection edge is usually beveled so you get that black line that runs around the edge of the cabinets. The backsplash is then placed on top of the formica. Usually, it is tile.

When replacement time comes, here is what you are faced with: 2cm, 3cm or 4cm [laminated] granite tops. 2cm=3/4". 3cm=1 and 1/8". 4cm is two pieces of 2cm glued together. Be mindful that 2cm may actually be 11/16" or it could be 7/8". It depends on who produced it. The same variables apply to 3cm.

So, if you are wanting to save your backsplash, remember it is going to start at 36" off the floor. Once the formica is stripped off, your base cabinet is going to be 34.5" off the floor. So, if you use 2cm or 3cm, there is going to be a gap somewhere. Either on the bottom of the granite, or between the top of the new counter and the existing tile backs.

If you do 4cm, you can re-strip the cabinets with 1X2 furring strips and the laminated edge will cover the furring strips. The counter height should match the existing tile, or within a caulkable margin. The problem here is two-fold. One, you must 'handle' the material about 5 times to get a tight lamination. It is not a matter of simply gluing a secondary piece on the bottom and calling it good. Thus, with all the additional handling, the costs go up.

The second problem is grain match. As people's tastes in stone continue to get more sophisticated, they tend to like unique stone with movement. If all your cabinets are straight runs, no big deal. We can make the grain match. Got any funky angles, big round corners, want the top grains to match properly? Big problems. With any of these conditions, something has to give. And what 'gives' is grain match. So, if the grain match is no big deal to you, this solution will work. However, most of our clients expect it to be right [as do we], so lets go back to 2cm or 3cm.

Furr up the tops to meet the backsplash and run a piece of wood trim under the tops to hide the height variation. This works.

Leave the counters on top of the cabinets and run a piece of tile trim or stone trim to cover the void between the counters and backsplash. This works.

Now, lets look at economics. I'm going to use some 'average' numbers. Let's say you are putting in some very nice 3cm granite. Let's say it will cost $4000. The average backsplash will cost [labor and material] about $350. Am I going to go into contortions trying to save the $350 component? Economically, no.

There are always variables, and if you have individual questions, I'll be happy to answer them, but this should give you a basic overview of some considerations you might want to ponder. No one likes expensive surprises. We would be included in that group.

Saturday, March 22, 2008

Leathered finish

We are now able to offer 'leathered' finishes on any stone. We also do honing and brushing.

The leather finish is kind of like a river-washed effect. As if the softer portions of the stone had been eroded by a natural stream over many, many years. To the touch, it has the slightest texture as you run your fingers over it. It also takes away most of the shine, although we can color enhance it to bring the uniqueness of the stone color back. But, it will remain a matte finish.

Several US slab distributors offer a very limited amount of colors in leathered stone. Usually in dark colors. [Cambrian Black seems to be used quite often]

Now, we can leather any stone. We are not limited to what their suppliers provide. We're running some Golden Crystal right now.

Any color you want can now be leathered, honed or brushed.

The leather finish is kind of like a river-washed effect. As if the softer portions of the stone had been eroded by a natural stream over many, many years. To the touch, it has the slightest texture as you run your fingers over it. It also takes away most of the shine, although we can color enhance it to bring the uniqueness of the stone color back. But, it will remain a matte finish.

Several US slab distributors offer a very limited amount of colors in leathered stone. Usually in dark colors. [Cambrian Black seems to be used quite often]

Now, we can leather any stone. We are not limited to what their suppliers provide. We're running some Golden Crystal right now.

Any color you want can now be leathered, honed or brushed.

Water Jet

We now offer the only stone water jet service in the state.

We can do signs, business inlays [logos in a conference table as an example], outdoor signage, decorative inlays in countertops. Whatever needs you may have, we have the technology to do it.

We just completed some onyx inlays for Todd Luster, who is doing the Warren theater in Moore, Ok.

There are several examples in the showroom.

We can do signs, business inlays [logos in a conference table as an example], outdoor signage, decorative inlays in countertops. Whatever needs you may have, we have the technology to do it.

We just completed some onyx inlays for Todd Luster, who is doing the Warren theater in Moore, Ok.

There are several examples in the showroom.

Thursday, March 13, 2008

Gambling

For most people, their home is their largest investment. Most are not into gambling on that investment. When it comes time to sell, the primary assets are the Kitchen and Master Bath. That is what we do for a living.

Since we are 100% digital, our work starts in a computer and stays there until a skilled fabricator finishes the polish by hand.

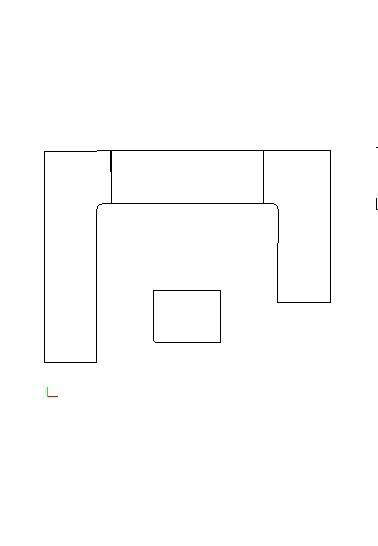

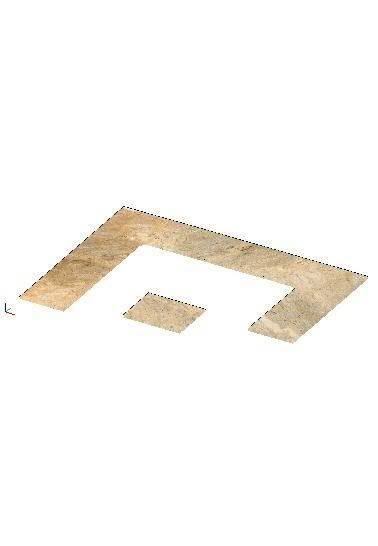

The above image is the bird's eye view of one of our client's kitchen. There is a sink in the top portion of the horse shoe, pretty much in the center. There is a free standing stove on the bottom right and the little piece goes on the other side of the stove. In the picture, the vertical lines on either side of the sink are seam locations. Most companies seam at the corners- we almost never do that, because that is where people look first.

The Stone choice is Crema Mara. It is very active with lots of pattern and color changes.

Next, I'm going to show you a 'normal' layout of this stone. All pieces except the sink piece come out of the first slab. The sink piece somes out of slab two, and it does not matter which corner you choose re the match. This one comes from the top left, which was the best, such as it is.

This method saves the most material. In this case, probably $400 worth of savings, if it was bought domestically [We actually imported this one].

Here's what your gamble looks like:

We're the second Stone Fabricator in the country using this new system. We got it in December and have used it numerous times.

Here is what the clients actual investment will look like:

The difficulty on this layout is the grain and color match on the sink section. In our layout, the colors match and the grain is right.

Did we use more material than the 'normal' one? Yes. Does it show? Yes, it does.

The system actually shows you real time changes as you maneuver the parts over the picture of the stone. Sometimes, it takes a while to get it right. So be it. This one took two of us about 15 minutes to get the color and grain the way we wanted it.

There have been times where we actually changed the seam locations just to get the matches we wanted.

We're not gambling with your investment. We know exactly what it will look like before it ever hits the Sawjet.

2008

Its' been 13 months since I've updated this blog, and my how things have changed around here.

First, what is on the water right now:

From the Italians, we have a Marble order en route. It should be here in about 3 weeks.

Emperador 2 and 3cm.

Black Guinea 2cm. A very old Italian Quarry. [Guinea is pronounced Gwen-Nay] Our Italian rep is slowly teaching me some Italian. And, I do mean Slowly.

Calacatta Fantastico Light. 2cm. Very pretty white.

Calacatta Fantastico Dark. 3cm. A little darker, but equally pretty.

Breccia Oniciatta. 3cm. This stuff is really pretty, but really fragile. When we open the container, my guys will want to shoot me when they see it. It is difficult to work with.

From the Brazilians, I finished one yesterday. It should be here by the end of April.

2 bundles of 3cm Soapstone with the gorgeous white veining.

1 bundle of 3cm Supreme. A brand new offering from one of our favorite suppliers. Vibrant golds and blacks. This company is famous for their Classico Supreme. I'm guessing this is from a different part of that quarry because the golds and blacks are very similar.

2 bundles of 3cm Napoleon. We got one late last year from the same supplier. It was the best looking Napoleon I've seen in 5 years. Really top-flight. Great colors with no orange or peach.

1 2cm and 1 3cm Giallo Ornamental. Subtle whites, but very elegant.

I'll deal with the hardware and software changes in a later post.

First, what is on the water right now:

From the Italians, we have a Marble order en route. It should be here in about 3 weeks.

Emperador 2 and 3cm.

Black Guinea 2cm. A very old Italian Quarry. [Guinea is pronounced Gwen-Nay] Our Italian rep is slowly teaching me some Italian. And, I do mean Slowly.

Calacatta Fantastico Light. 2cm. Very pretty white.

Calacatta Fantastico Dark. 3cm. A little darker, but equally pretty.

Breccia Oniciatta. 3cm. This stuff is really pretty, but really fragile. When we open the container, my guys will want to shoot me when they see it. It is difficult to work with.

From the Brazilians, I finished one yesterday. It should be here by the end of April.

2 bundles of 3cm Soapstone with the gorgeous white veining.

1 bundle of 3cm Supreme. A brand new offering from one of our favorite suppliers. Vibrant golds and blacks. This company is famous for their Classico Supreme. I'm guessing this is from a different part of that quarry because the golds and blacks are very similar.

2 bundles of 3cm Napoleon. We got one late last year from the same supplier. It was the best looking Napoleon I've seen in 5 years. Really top-flight. Great colors with no orange or peach.

1 2cm and 1 3cm Giallo Ornamental. Subtle whites, but very elegant.

I'll deal with the hardware and software changes in a later post.

Subscribe to:

Posts (Atom)